Avoiding delays, fines, or losses requires a clear understanding of customs procedures, the regulatory requirements in each country, and how to anticipate hidden costs.

Expanding into Latin America requires a precise reading of the regulatory, operational, and tax frameworks that shape the process. It involves understanding how customs authorities operate, which requirements apply to electronic devices, and identifying the key factors that may affect project timelines, costs, and overall feasibility.

In this context, having clear criteria on what to do—and what to avoid—becomes decisive for an international operation to reach its intended destination on time and within budget. This Dos and Don’ts outlines the main points companies must evaluate when introducing technology equipment into the region, drawing on proven logistics practices and the accumulated expertise of those who manage these operations daily.

1. Technical Regulations and Permits

DO:

Conduct a country-specific assessment to identify prior authorizations, technical certifications, and the agencies involved—for example, ANATEL in Brazil, NOMs and labeling in Mexico, and MTC approvals in Peru.

DON’T:

Assume the region operates under uniform rules or that tech equipment can enter without mandatory validations.

How Aerodoc addresses this point:

- Manages permits and certifications, including technical labeling and compliance with relevant authority requirements.

- Assesses whether equipment requires pre-approval for entry into the destination country.

- Serves as IOR/EOR, taking on the legal and documentary responsibility to operate without a local entity.

- With a legal presence in Argentina, Mexico, Peru, Colombia, Chile, and Panama, Aerodoc can invoice and collect payment in local currency, and subsequently transfer the FOB value to the customer.

2. Duties, Associated Costs, and Regulatory Shifts

DO:

Build a comprehensive cost model that includes duties, port fees, warehousing, inspections, and recent regulatory changes.

DON’T:

Overlook the frequent shifts in customs policies, such as in Argentina, where tariff adjustments and new systems are standard.

How Aerodoc addresses this point:

- Through its DDP with IOR service, it manages shipping, customs clearance, taxes, duties, and final delivery.

- Keeps operations aligned with regulatory updates, helping avoid unexpected charges or cost overruns.

- Identifies non-obvious country-specific costs (such as labeling, certifications, and inspections) to help customers plan accurately.

3. Technical Documentation, Inspections, and Declarative Accuracy

DO:

Thoroughly document each shipment with datasheets, photos, serial numbers, technical specifications, packaging details, and proper product classification.

DON’T:

Ship cargo with incomplete paperwork, assume that physical inspection is unnecessary, or rely on third-party data without cross-checking. Documentation errors are the leading cause of customs holds.

How Aerodoc addresses this point:

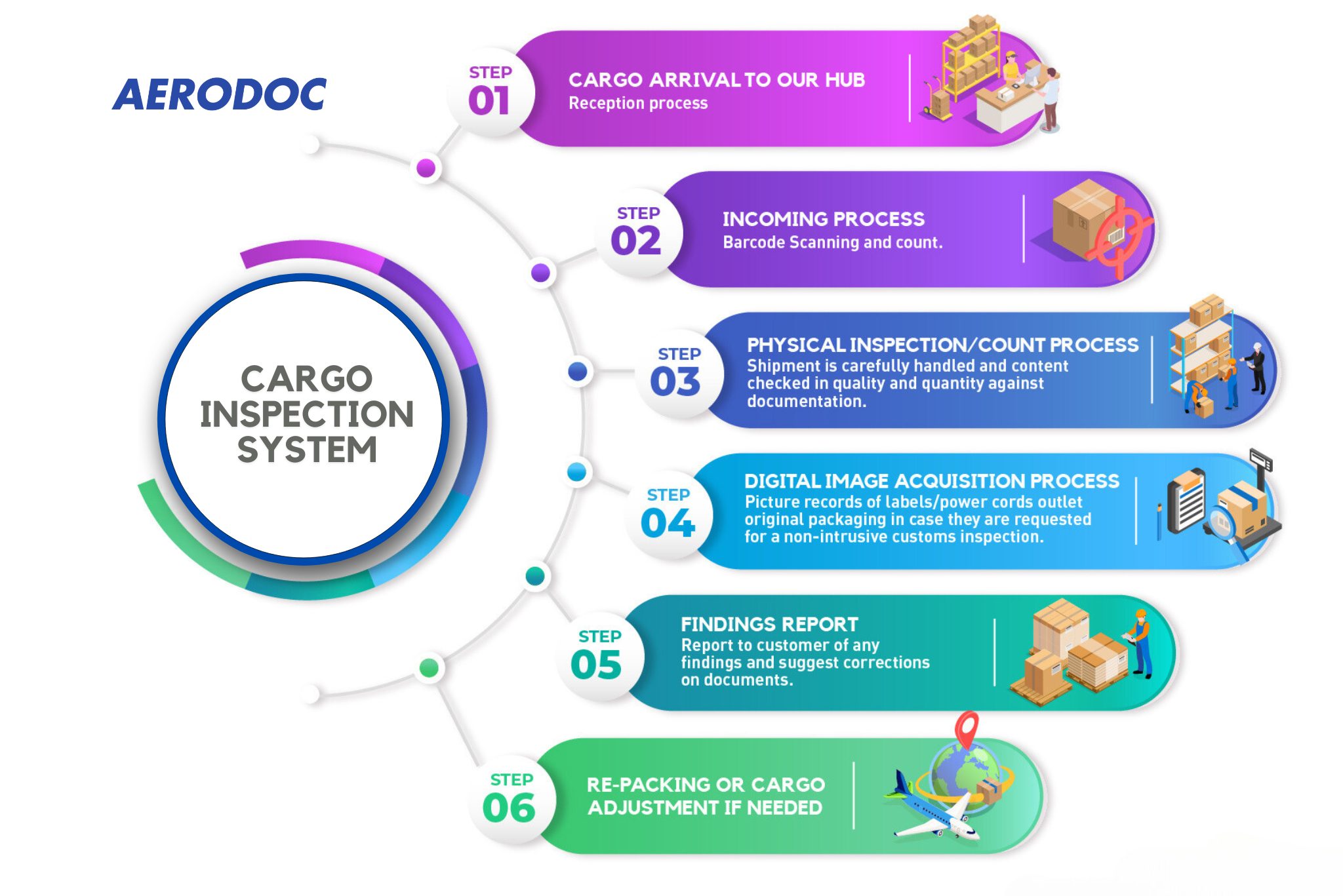

- Conducts origin inspections to verify alignment between the declared information and the physical goods.

- Validates packaging, labeling, and the technical condition of the equipment before dispatch.

- Adjusts documentation to prevent valuation discrepancies, rejections, or penalties at destination.

4. Tariff Classification

DO:

Accurately determine the NCM/HTS code, considering whether the equipment is subject to control, intervention, or requires a technical permit.

DON’T:

Rely on codes suggested by global vendors without confirming their compatibility with the destination country’s regulations.

How Aerodoc addresses this point:

- Defines the correct classification for each device and piece of equipment.

- Applies technical and documentary pre-compliance to avoid border rejections.

5. Time Planning, Operational Windows, and Customs Management

DO:

Develop a realistic timeline that factors in permit approvals, inspections, and customs clearance, tailored to each country.

DON’T:

Apply global-standard lead times to Latin America, or commit to installation dates without validating customs processing times.

How Aerodoc addresses this point:

- Builds custom SLAs based on experience across 172+ countries.

- Operates with multi-zone teams and follow-the-sun models to maintain operational continuity and eliminate downtime across time zones.

- Anticipates market-specific bottlenecks and adapts the import strategy to local customs behavior.

6. Last Mile, Security, and Technical Handling

DO:

Assess geographic risks, accessibility, vehicle restrictions, high-risk areas, and the need for technical handling (white glove) based on the equipment type.

DON’T:

Rely on operators without technical expertise to handle sensitive equipment, or ship to risk zones without local planning.

How Aerodoc addresses this point:

- Designs route plans and security protocols tailored to high-risk areas.

- Provides technical handling services, including white-glove delivery, preliminary assembly, and site-readiness checks.

- Develops custom packaging for antennas and bulky equipment to minimize costs and prevent damage.

7. Warehousing Strategy, Consolidation, and Regional Supply

DO:

Use a strategically located hub to consolidate inventory, shorten lead times, and reduce fixed costs. Miami provides the most efficient base for supplying Latin America.

DON’T:

Set up a warehouse in the region without understanding actual operational costs, inventory risks, turnover rates, or the specific needs of each market.

How Aerodoc addresses this point:

- Integrates with SAP systems and provides full traceability to manage stock, orders, and technical configurations.

- Optimizes regional supply from Miami, lowering expenses and reducing time-to-market.

If your company needs to import or distribute technology in Latin America, Aerodoc’s team can support you at every stage: tariff classification, local certifications, customs management, importer of record services, inventory administration at our Miami hub, technical handling, and specialized deliveries.

Let’s discuss your projects and define the most suitable operational and regulatory strategy for each destination country. Our team is available to support you in carrying out secure, predictable, and cost-efficient operations across the region.

Contact us today.

Q&A

- What are the key legal risks companies face when importing and distributing technology in Latin America? Legal risks include non-compliance with country-specific certifications, errors in tariff classification, and operating without proper IOR/EOR representation. These can lead to customs holds, financial penalties, or product rejections.

- How can companies optimize cost structures when importing tech products into Latin American markets? By implementing a DDP model with localized warehousing, accurately forecasting hidden costs (e.g., labeling, inspections), and monitoring regulatory shifts, businesses can avoid budget overruns and optimize their landed-cost model.

- What role does Miami play in regional logistics for tech distribution in Latin America? Miami acts as a strategic consolidation hub, enabling faster lead times, lower inventory costs, and centralized supply chain control. It supports streamlined distribution across LATAM with integrated warehousing and SAP-based traceability.

- How can delays in customs clearance be minimized when importing electronic equipment into LATAM? Delays can be mitigated by pre-validating documentation, securing technical permits in advance, applying precise HS/NCM codes, and adapting timelines to local customs behaviors and inspection protocols.