Aerodoc manages global projects, shortens delivery times, and prevents logistical errors through a single vendor model.

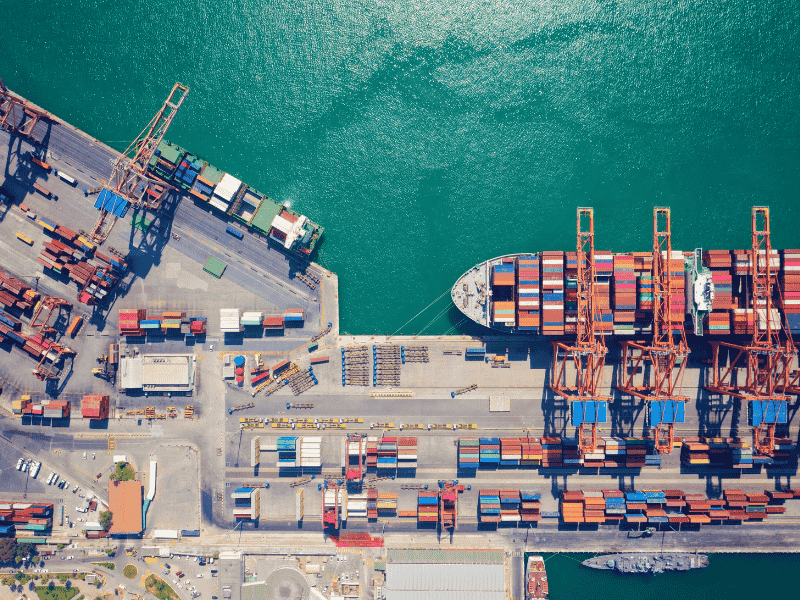

Tech companies operating in data centers, telecommunications, systems integration, and AV/IT often carry out simultaneous projects across different countries, working with tight schedules and fixed installation windows. At the same time, these companies require control, standardization, and visibility. Their operations involve serialized equipment, technical kits, sensitive materials, and high-value assets, where any operational misstep directly affects costs, SLAs, and brand reputation.

An international warehouse network managed by a single provider, such as the one offered by Aerodoc, allows for centralizing inventory oversight, implementing uniform processes across all countries, and coordinating regional deployments from a single control point. This approach allows stock to be pre-positioned, lead times to be cut, procurement to be decoupled from installation, and swift adjustments to be made to shifting scopes or customer priorities.

Benefits of Partnering with Aerodoc’s Global Warehouse Network

1) Fewer Barriers to Global Expansion (no upfront investment in warehouses or local operations)

For project-driven tech companies, setting up proprietary infrastructure in every market is costly and time-consuming. Aerodoc allows businesses to expand without allocating resources to warehouses, personnel, local systems, or operational frameworks.

2) Specialized Oversight of Tech Inventory (serial numbers, models, kits)

In the tech sector, inventory issues often stem from incorrect models, quantities, or serial numbers; stock mixing; or incomplete kits. Aerodoc validates that each item’s model, quantity, and serial number match the expected specs before storage. Items are tagged, identified, and tracked through Aerodoc’s management system, providing continuous visibility into what each item is, where it’s located, and which project it supports.

Aerodoc also manages customized kits, sets of equipment assembled specifically for a site, customer, or project (such as racks, switches, accessories, and spare parts). This guarantees that, at the time of dispatch, all the correct components are shipped together, avoiding missing items, configuration errors, or reshipments that could directly impact installation timelines.

3) Real-Time Global Visibility and Inventory Governance

Aerodoc runs entirely on SAP, logging every movement—inbound, storage, repackaging, and outbound—to maintain full traceability. Customers have continuous access to inventory data, with consolidated information by project and destination, as well as real-time updates on shipment status. This level of visibility is key for tech companies, where multi-country coordination, overlapping projects, and last-minute changes are common.

4) Fast and Standardized Execution (meeting SLA commitments)

In tech rollouts, “time-to-site”, the total time from when equipment is ready to ship to its actual arrival at the installation site, is a key metric. Aerodoc offers a 24-hour SLA and manages the entire process: picking, packing, project- or destination-based consolidation, labeling, documentation, and coordination with carriers or couriers. Fewer operational delays mean fewer technicians left waiting and fewer missed installation windows.

5) End-to-End Operation (fewer vendors, fewer failure points)

Aerodoc’s warehouse network is further strengthened by its integrated logistics approach, which includes receiving, storage, kitting, domestic and international distribution, and full door-to-door coordination when needed. This simplifies the model by consolidating everything under one vendor, with one system and improved traceability.

Strategic Hub in Miami for Reaching LATAM and the US

In addition to its global warehouse network, Aerodoc operates Aerowork, a wholly owned subsidiary specifically designed for companies looking to expand into the US without setting up a local infrastructure.

“Some companies may want to start selling in B2B marketplaces but do not want to keep the full stock or incur high costs, because they are not aware of companies like us and the time and cost savings we offer,” explains María Carolina Muller, VP of Business Development at Aerodoc.

Leveraging Aerodoc’s more than 25 years of expertise in integrated logistics, Aerowork centralizes fulfillment operations—including sales across major US marketplaces—inventory management, and operational support into a single model. Bilingual Spanish support allows regional teams to coordinate orders, stock, and shipments without language barriers.

Aerowork delivers a fully integrated global logistics solution, covering pickup at origin, international transport, customs management—including acting as Importer of Record (IOR) and Exporter of Record (EOR)—and final delivery. This facilitates companies to run the entire supply chain through a single provider, with clearly defined responsibilities from start to finish.

The offering includes access to office or coworking spaces, allowing businesses to operate, coordinate teams, and dispatch orders from a single US hub through a single vendor and a single system.

If your operations require inventory management across strategic international hubs, our team is ready to support you.

Q&A

- How Can a Global Warehouse Network Scale to Meet Growing Demand in Technology Projects? By analyzing demand patterns, deploying strategic hubs, and integrating WMS with ERP systems, ensuring responsiveness without compromising SLAs.

- What Criteria Should Be Considered When Selecting Strategic Locations for a Global Warehouse Network? Market proximity, logistics infrastructure, customs efficiency, skilled labor, and multimodal transport are key to reducing costs and delays.

- What Cybersecurity Measures Are Essential to Protect Digitized Inventory Within a Global Warehouse Network? Data encryption, real-time monitoring, and role-based access help secure digital inventory and ensure compliance.

- How Can a Global Warehouse Network Be Integrated with a Client’s ERP System to Ensure Full Traceability? Through APIs and middleware, WMS platforms connect to ERPs such as SAP and Oracle, enabling real-time, cross-border inventory control.